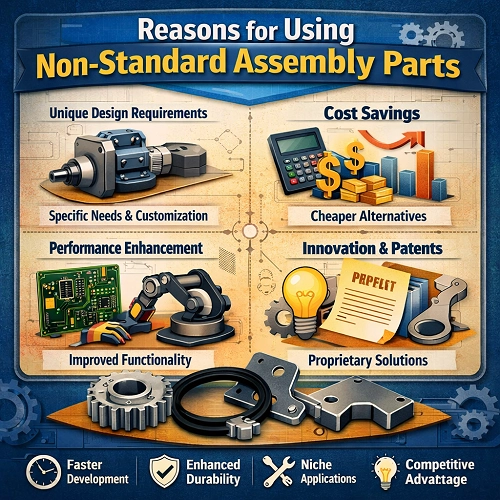

In modern manufacturing and engineering, standard parts — such as ISO fasteners, commercially off-the-shelf (COTS) components, and industry-approved modules — are often the first choice. Their universality promotes interchangeability, simplifies procurement, and enables predictable quality. Yet, engineers frequently select non-standard assembly parts for their products. These bespoke or customized components can be anything from specially machined fasteners and proprietary springs to unique electronic modules.

Choosing non-standard parts is not a trivial decision. It carries implications across design, cost, supply chain, quality control, and long-term lifecycle. But when the application demands precision performance, optimization, or differentiation, non-standard parts can be decisive advantages.

Standard parts adhere to widely accepted specifications (e.g., DIN, ANSI, ISO). However, not all applications conform to generic geometry. A non-standard part may be needed when:

A non-standard component can integrate multiple functions, thereby reducing total part count and assembly complexity. For example:

Integration improves assembly accuracy, improves repeatability, and can minimize tolerances stack-up in complex mechanisms.

Standard parts are often made from general-purpose materials (e.g., carbon steel, common plastics). However, certain applications demand:

Non-standard parts let engineers specify advanced materials that match operational conditions precisely.

In some industries (medical, semiconductor fabrication), components must meet stringent cleanliness and outgassing limits. Custom plating, passivation, coatings, or manufacturing processes (e.g., vacuum baking) may be required.

Critical systems (avionics, nuclear controls, life-support equipment) are designed with safety margins and redundancy. Non-standard parts are often built to:

Standard parts typically do not offer the predictability or certification required for such extreme applications.

For regulated industries (military, aerospace, automotive safety), parts must meet detailed documentation and traceability requirements. Custom parts allow:

This control increases confidence in performance and supports compliance audits.

Products that differentiate through unique mechanical, electrical, or functional features often rely on bespoke components. Examples include:

These non-standard parts become part of the company’s intellectual property, protecting competitive advantage.

Standard parts impose design constraints by definition. Custom components enable novel architectures and innovation that standard catalogs cannot support.

Although custom parts can increase part cost, they often reduce assembly labor and time. Design for Assembly (DFA) principles favor:

This reduces human error and total production time.

Custom parts can include design features specifically to support robotic assembly, such as:

This improves cycle times and reduces downtime due to part handling issues.

Standard parts may be discontinued by suppliers, forcing redesigns. In contrast, having proprietary non-standard parts under long-term contracts or controlled inventories can:

For companies with multiple product lines, custom parts can be shared across platforms, reducing the total number of unique components. This improves forecasting and inventory management.

While unit cost of custom parts may be higher than standard parts, total system costs can be lower due to:

For high volume products, custom tooling (progressive dies, injection molds) amortizes quickly. Design for Manufacturability (DFM) and economies of scale can make non-standard parts cost-effective compared to expensive assemblies of standard components.

Using non-standard parts also introduces challenges:

Mitigating these requires strong engineering change control, supplier qualification, and cross-functional planning between design, procurement, and manufacturing.

Non-standard assembly parts are not just bespoke versions of standard items. They are strategic tools that enable performance optimization, design innovation, reliability, and competitive differentiation. While they involve technical and logistical challenges, when applied thoughtfully they yield significant benefits across the product lifecycle — from performance and safety to manufacturing efficiency and total cost of ownership.