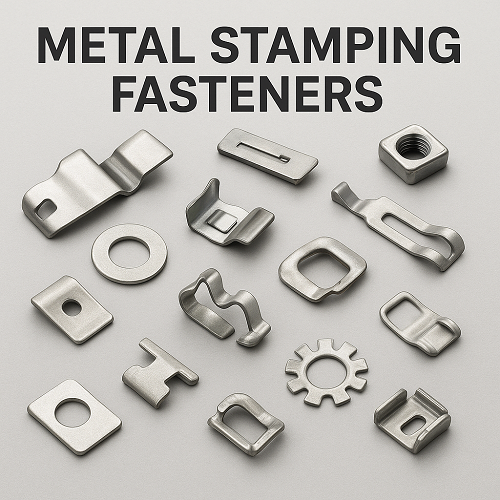

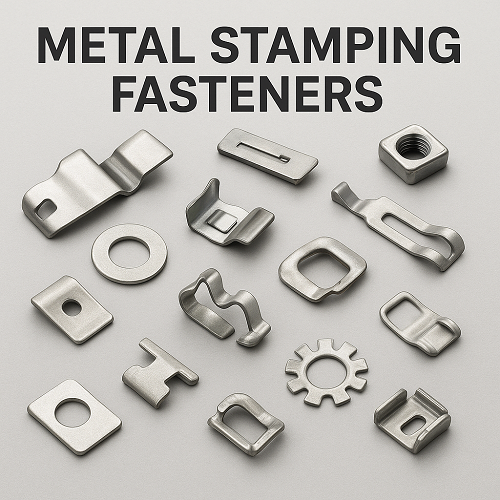

Metal stamping fasteners are integral components in modern manufacturing, providing structural integrity, assembly efficiency, and cost optimization across industries such as automotive, aerospace, electronics, construction, and consumer goods. These fasteners—ranging from clips, brackets, washers, and nuts to complex formed retainers—are produced through precision metal stamping processes that transform sheet metal into high-performance parts with tight tolerances.

Overview of Metal Stamping Technology

Definition and Process Flow

Metal stamping is a cold-forming manufacturing process that uses dies and presses to cut, bend, emboss, or form sheet metal into desired shapes.

For fasteners, the process typically involves:

- Blanking: Cutting flat shapes (blanks) from metal sheets or coils.

- Piercing: Creating holes or slots for assembly or function.

- Forming/Bending: Shaping the metal into three-dimensional geometries.

- Coining/Embossing: Enhancing surface finish or improving dimensional accuracy.

- Tapping/Threading (if required): Creating internal or external threads.

- Deburring and Surface Finishing: Removing sharp edges and improving corrosion resistance.

Stamping Press Types

- Mechanical Presses: High-speed presses ideal for thin-gauge materials and high-volume production.

- Hydraulic Presses: Offer higher forming force and control for thicker or more complex parts.

- Servo Presses: Provide programmable motion control, improving precision and repeatability in forming operations.

Die Configurations

- Single-Stage Dies: Perform one operation per stroke (ideal for low-volume production).

- Progressive Dies: Combine multiple operations in one tool, feeding a continuous metal strip through several stations.

- Transfer Dies: Move individual blanks between stations, suitable for large or complex fasteners.

Materials Used in Metal Stamping Fasteners

Material selection directly impacts fastener performance, durability, and manufacturability.

The most common materials include:

| Material |

Characteristics |

Typical Applications |

| Carbon Steel (Low, Medium, High) |

High strength, cost-effective, easily formable |

Automotive brackets, structural fasteners |

| Stainless Steel (AISI 300, 400 Series) |

Corrosion resistance, good mechanical properties |

Aerospace clips, marine fasteners |

| Aluminum and Alloys |

Lightweight, corrosion-resistant, conductive |

Electronics housings, lightweight assemblies |

| Copper and Brass |

Excellent conductivity, ductility |

Electrical terminals, grounding fasteners |

| Nickel Alloys (Inconel, Monel) |

High-temperature and corrosion resistance |

Aerospace and chemical processing equipment |

Material properties such as yield strength, elongation, and hardness determine feasible forming limits and required press tonnage.

Tooling and Die Design Considerations

Precision tooling design is at the core of producing high-quality metal stamping fasteners. Key design factors include:

Die Material and Coating

- Tool Steels (D2, A2, M2): Provide wear resistance and toughness.

- Carbide Inserts: Used in high-volume or high-wear applications.

- Surface Coatings (TiN, TiCN, CrN): Improve lubricity, reduce friction, and extend die life.

Clearance and Tolerances

The die clearance—typically 5–10% of material thickness per side—directly influences burr height, part accuracy, and tool wear. Precision fasteners often require tolerances within ±0.01 mm.

Strip Layout Optimization

Efficient strip layout reduces material waste and improves feed consistency. CAD/CAM software assists in simulating forming stresses and optimizing punch progression.

Process Optimization and Automation

Coil Feeding and Straightening Systems

Automatic coil feeders ensure continuous material flow with precise alignment, reducing downtime and improving throughput.

In-Die Sensors

Modern dies incorporate sensors to monitor pressure, alignment, and part ejection—enhancing safety and enabling predictive maintenance.

Robotic Handling and Vision Inspection

Automated pick-and-place systems and vision-based quality checks streamline secondary operations such as sorting, packing, or assembly.

Post-Stamping Operations

After stamping, fasteners often undergo several finishing and conditioning steps:

- Heat Treatment: Enhances mechanical strength and fatigue resistance.

- Deburring and Tumbling: Removes sharp edges to prevent assembly damage.

- Surface Treatments: Includes zinc plating, phosphating, anodizing, or passivation for corrosion protection.

- Threading/Forming: Additional mechanical features such as knurling or thread forming may be integrated.

- Quality Control: Dimensional inspections, tensile testing, hardness testing, and salt-spray corrosion testing ensure reliability.

Common Types of Metal Stamping Fasteners

- Spring Clips & Retainers: Provide holding force in automotive interiors or electrical housings.

- Stamped Nuts & Washers: Used for lightweight fastening and load distribution.

- Panel Fasteners & Brackets: Connect sheet assemblies and enclosures.

- Threaded Inserts & Cages: Enable mechanical fastening in thin materials.

- Electrical Contacts & Terminals: Ensure conductivity in electronic assemblies.

Each type requires unique forming geometry and performance characteristics based on application loads and environmental conditions.

Quality Assurance and Standards

To maintain consistency, manufacturers adhere to international standards such as:

- ISO 9001 / IATF 16949: Quality management for automotive and industrial suppliers.

- ISO 2768 / DIN 6930: Tolerancing standards for stamped parts.

- ASTM A1008 / A240: Material property standards for carbon and stainless steels.

- RoHS / REACH Compliance: Restriction of hazardous materials for global markets.

Advanced quality tools like Statistical Process Control (SPC), Failure Mode and Effects Analysis (FMEA), and Coordinate Measuring Machines (CMM) are used to monitor dimensional accuracy and process stability.

Advantages of Metal Stamping Fasteners

- High Precision and Repeatability: Ideal for large-scale production.

- Cost Efficiency: Minimal waste and low per-part cost at volume.

- Design Flexibility: Capable of producing complex geometries.

- Material Versatility: Supports a wide range of alloys and thicknesses.

- Automation Compatibility: Easily integrated with robotic and inspection systems.

Emerging Trends and Innovations

- Micro Stamping: For miniature fasteners in electronics and medical devices (tolerances down to ±0.002 mm).

- Hybrid Manufacturing: Combining stamping with laser cutting or additive manufacturing for prototyping.

- High-Strength Steel and Titanium Stamping: To reduce weight in automotive and aerospace sectors.

- Sustainability: Use of recyclable materials and closed-loop lubrication systems to reduce environmental impact.

- Smart Tooling: Integration of sensors and real-time monitoring for predictive maintenance and reduced downtime.

As industries demand lighter, stronger, and more cost-efficient assemblies, advancements in tooling design, process control, and intelligent manufacturing will continue to redefine what is possible in metal forming technology.